Fiber Microlens for Optical Coupling Elements

Description:

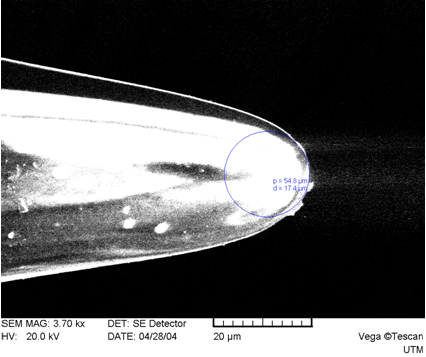

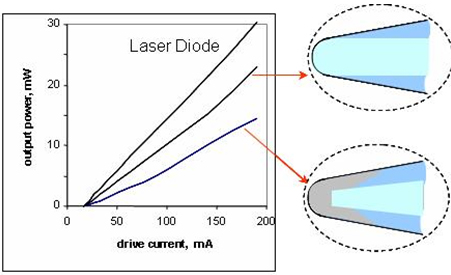

The original making method of fiber optic components was elaborated. Tapered end with microlens was formed by a combine method of chemical etching and fusion process. Optical fiber was immersed slowly in an acid etchant to obtain the conical shape of fiber ends. To form fusion hemispherical lens the fiber end was heated by electric arc discharge. The microlens diameter is determinated by the duration and current density of the arc discharge. Characteristics of output power from fiber optic, for microlenses with radius of lens R=8 μm fabricated by the used only electric arc discharge (curve 1) and fabricated by the combine chemical etching and fused methods (curve 2) is shown in Fig.1.

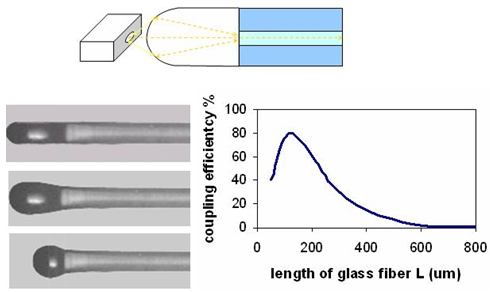

For the coupling of high-power laser diodes with optical fibers were designed and manufactured convex microlens on the homogeneous glass fiber fusion-spliced to the fiber optic. The efficiency of input radiation is depended not only on the curvature, but also on the length of the lens. Lenses with radius of 10 to 300 microns and length L of 50 microns to 3 mm were constructed and studied for various operating mode.

Innovative Aspect and Main Advantages:

- Decrease of coupling losses of laser diodes to optical systems in fiber optic communication;

- Diminish in number of coupling elements;

- Simplification and reduction in price of coupling technology

Areas of Application:

Fiber communication system, pumping of Er+ - doped devices.

Stage of Development:

The microlenses was setup in optoelectronic module and tested in Kursk State University, Russia.

a)

b)

Fig.1 Microlens (a), Characteristics of output power (b)

Fig.2 Convex microlens for various operating mode.

Contact Details:

Technical University of Moldova

Contact persons:

Valerian DOROGAN, vice-rector

Sergiu ZAPOROJAN, department of scientific investigations

Address:

Republic of Moldova, Chisinau, 168, Stefan cel Mare Ave.

Tel/Fax:

+ (373 22) 23 54 37,

+ (373 22) 23 54 05

E-mail:

dorogan_lme@yahoo.com

Warning: mysql_fetch_assoc() expects parameter 1 to be resource, boolean given in /usr/home/incubator/public_html/lib/na_db.php on line 76

Warning: mysql_free_result() expects parameter 1 to be resource, boolean given in /usr/home/incubator/public_html/lib/na_db.php on line 81

VIRTUAL EXHIBITION

Warning: mysql_fetch_assoc() expects parameter 1 to be resource, boolean given in /usr/home/incubator/public_html/lib/na_db.php on line 76

Warning: mysql_free_result() expects parameter 1 to be resource, boolean given in /usr/home/incubator/public_html/lib/na_db.php on line 81